What is the hot end? The hot end is the part that melts the plastic; it is the nozzle, or "pen" of the 3D printer. This is arguably the most important yet the most difficult part to make for the RepRap. Why? Because in order to make the best hot end, you need to either buy custom parts, or be able to machine metal. The extruder/hot end combination are a major factor in print quality, and it is important to get this part right.

For most people, I seriously recommend buying a kit or a premade hot end unless you have the ability to machine quality parts. A few months ago, when I was deciding what to do about the hot end I was still an engineering student (electrical) and I had a few friends who were mechanical engineers with a lot of machining experience. The combination of having access to the machine shop via my friends and the fact that a few months ago there were no quality hot end kits for a reasonable price led me to design and build my own..

What Makes Up a Hot End?

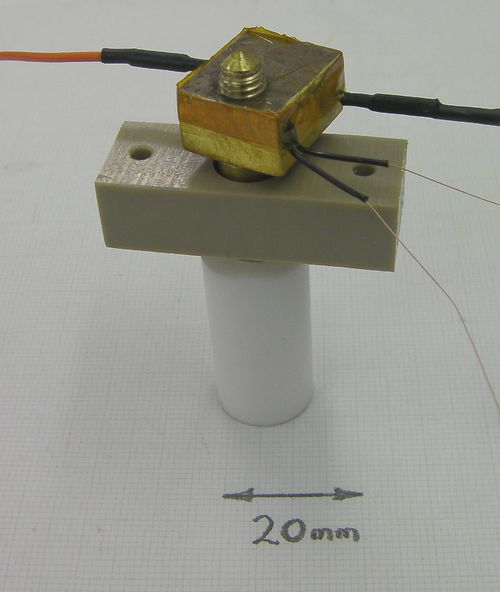

Let's start with the most obvious part of the hot end. The thing that makes it hot! Somehow we have to heat up the plastic enough for it to melt and flow through the nozzle. One of the easiest and most common way to heat up the metal nozzle is with a resistor, specifically a wirewound resistor. A wirewound resister is desirable because it generates heat well and also handles heat well, an added benefit is that they typically have low resistance. Having low resistance is important because the more current which flows through the resistor, the more heat it generates. To get high current, you either need a high voltage or a low resistance (ohms law), and it is easier to buy a lower valued resister than to generate high voltage. The resistor is typically embedded in an aluminum or brass heating block. You can see this in the picture below.

|

| The hot end with the resistor and thermistor installed. |

The other parts of the hot end differ depending on the design. Regardless, the rest of the hot end will allow you to mount it to the cold end (such as Wade's Extruder) and will insulate the plastic pieces of the cold end from the heat. This is why materials such as PEEK, and PTFE are used; they insulate the plastic parts from heat VERY well. The downside is that these two materials are expensive and typically are only available online.

NOTE: This is very important. If you are using PTFE for any parts of your designs you must not forget that it expands when it is hot. It will get hot. Forgetting this fact can make a seemingly great design not work at all.

Hot End Information

There are so many pages dedicated to hot ends on the wiki, it is a bit overwhelming if you don't know where to start. Currently (October 2011), there seem to be three popular options for a new hot end which are very successful.

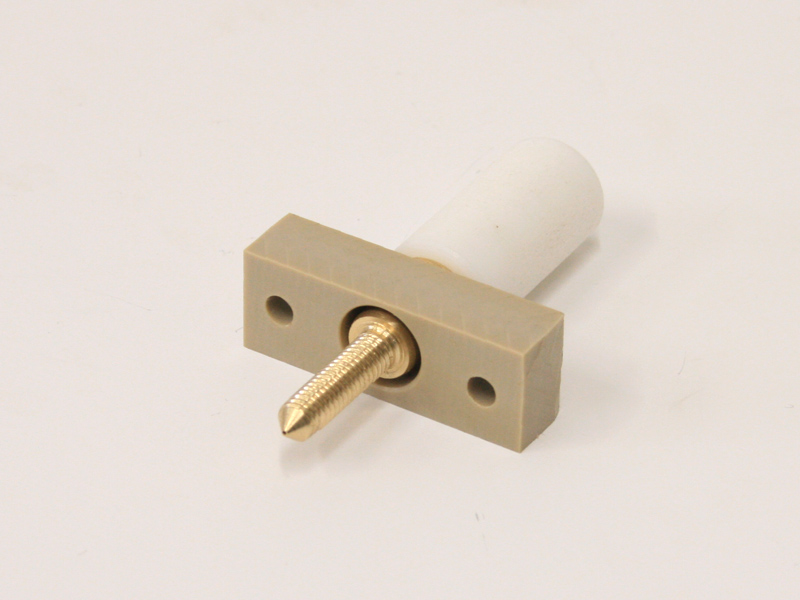

|

| Camiel's Hot End |

|

| The J Head Nozzle (MK III-B |

"The PTFE tubing also acts to "bridge" the joint between the PEEK insulator and the brass nozzle/heater. By not having the filament in contact with this joint it is hoped that any possibility of leakage will be completely eliminated." (A quote from the wiki)

Though this design requires a complicated machined part, it does have a very low part count and would be very easy to assemble/install.

|

| Arcol's Hot End v3.0 |

Keep in mind, I have not purchased this nozzle, nor the J Head nozzle, so my thoughts here are all speculation based on my experience with what I do have. This nozzle seems to be quite complicated, with many different parts. This adds to it being more difficult to assemble but it also means that if one part breaks, you can replace just the one small part (if you can make or buy it individually). The thing that really impresses me with this nozzle is how the wiring is handled. In my own design, I have struggled with mounting the wires, this design handles the wires beautiful and makes it super easy to remove the hot end.

One thing I have noticed (which could be incorrect) is that neither the J Head nozzle, nor Arcol's nozzle, is available for both 3mm and 1.75mm filament. It seems that these kits are only for the 3mm filament. I would love to see a design which makes it easy to switch filament size depending on your needs. Regardless, I recommend going with 3mm to start out with if this is you first RepRap.

Conclusion

Keep in mind, these three options are just what I believe to be the most popular hot ends in the community. There are countless other designs which may or may not be more or less successful than any of the three I spoke of here. I hope that this post demystifies the hot end a bit!

What design do you use? Have any of you used multiple designs and can compare the differences in print quality?