I ended up needing all of the these things during my built at some point and I believe that having all of them before you start will really help you out.

Materials

- Electrical Tape (or Heat Shrink)

- Liquid Electrical Tape

- Blue Painters Tape

Even if you bought pre-built electronics, you will still want to have electrical tape; sometimes wires break. Electrical tape is also useful for some quick fixes that regular tape can't handle. As far as liquid electrical tape goes, this is an odd one. When you are making your own electronics and need to insulate something that is not a nice shape, liquid electrical tape works wonders. Another possible use is for connections where you don't want the electrical tape to unravel. It's one of those things you will always use once you have it.

Blue painters tape is good thing to have once you finish building your printer. Even though it is not the best material to print on, it is a great material to experiment on with your first prints.

Tools

- Hot Glue Gun

- Files

- Level

- Ruler/Caliper

- Multimeter

- Soldering Iron

Files are come in very handy if you need to file down one of your printed parts during the build. During my build I did not have a good set of files; in hindsight, I really wish that I had files during my build. Files also can come in handy for removing undesirable parts from your initial prints.

I know that this one might be obvious but I can't stress the need for a level enough, and I don't mean the level app that you have on your smart phone! Sure the phone one is useful but unless you can accurately calibrate it, it is useless. Making sure each section of your build is level is VERY important for getting high quality prints and making sure parts like the X-carriage moves correctly without getting stuck. A ruler and/or caliper is also great to have for a similar reason. It will help you align your build frame, make sure parts are the right size, and helps you calibrate your printer once it's put together. Make sure you have a quality ruler.

Sure I would recommend having a full set of electronics test equipment, but it is not necessary. You don't need an oscilloscope, but you do need a multimeter. Even having a cheapo $2 multimeter from eBay is better than not having one at all. It is VERY important to make sure your supply voltages are correct for the electronics, and a multimeter is invaluable if you have any problems with your electronics.

Having a soldering iron is important even if you have pre-built electronics. You might need to solder connectors to your stepper motors or to your ends-stops; you might even need to repair a small part of your circuit if something goes wrong. It doesn't have to be a nice soldering station, but make sure you get a soldering iron.

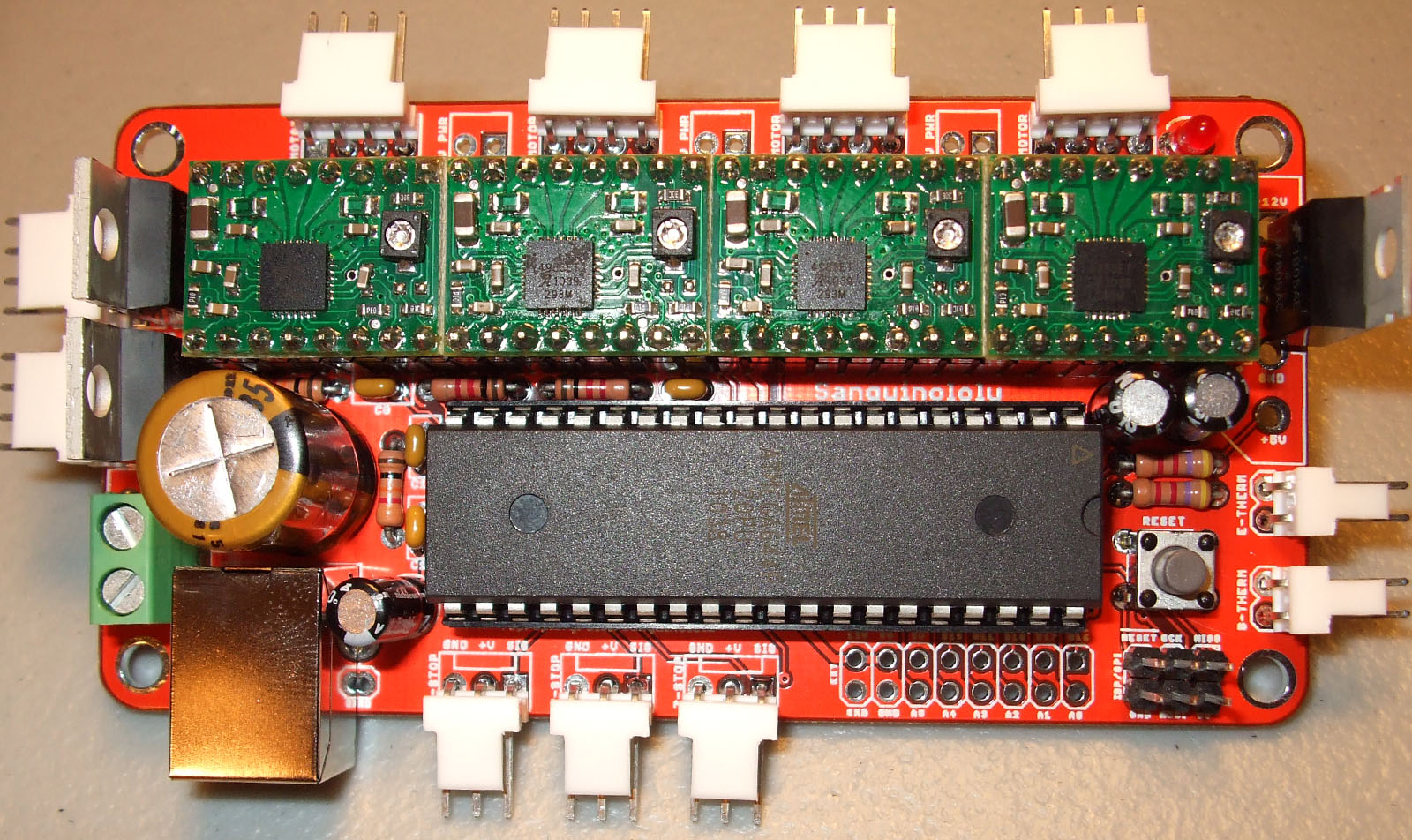

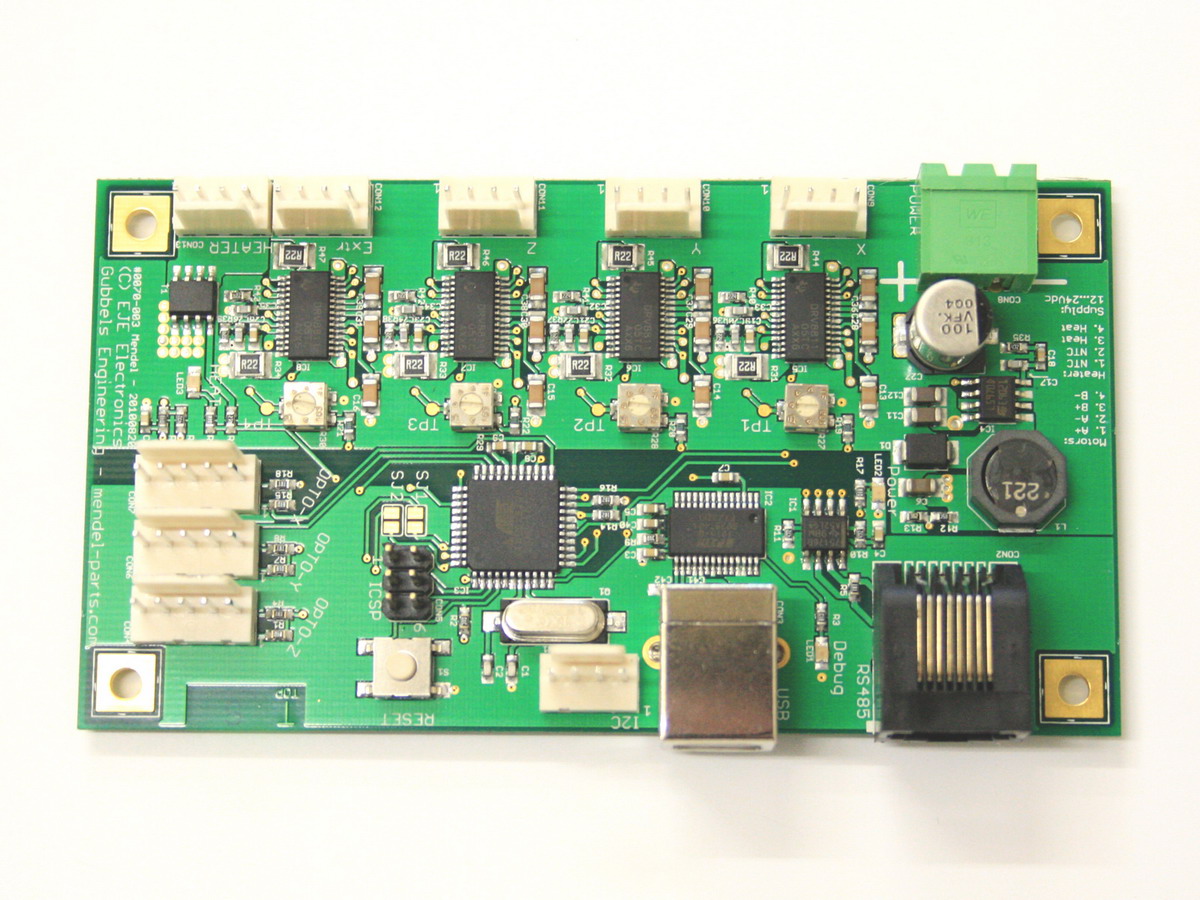

Software

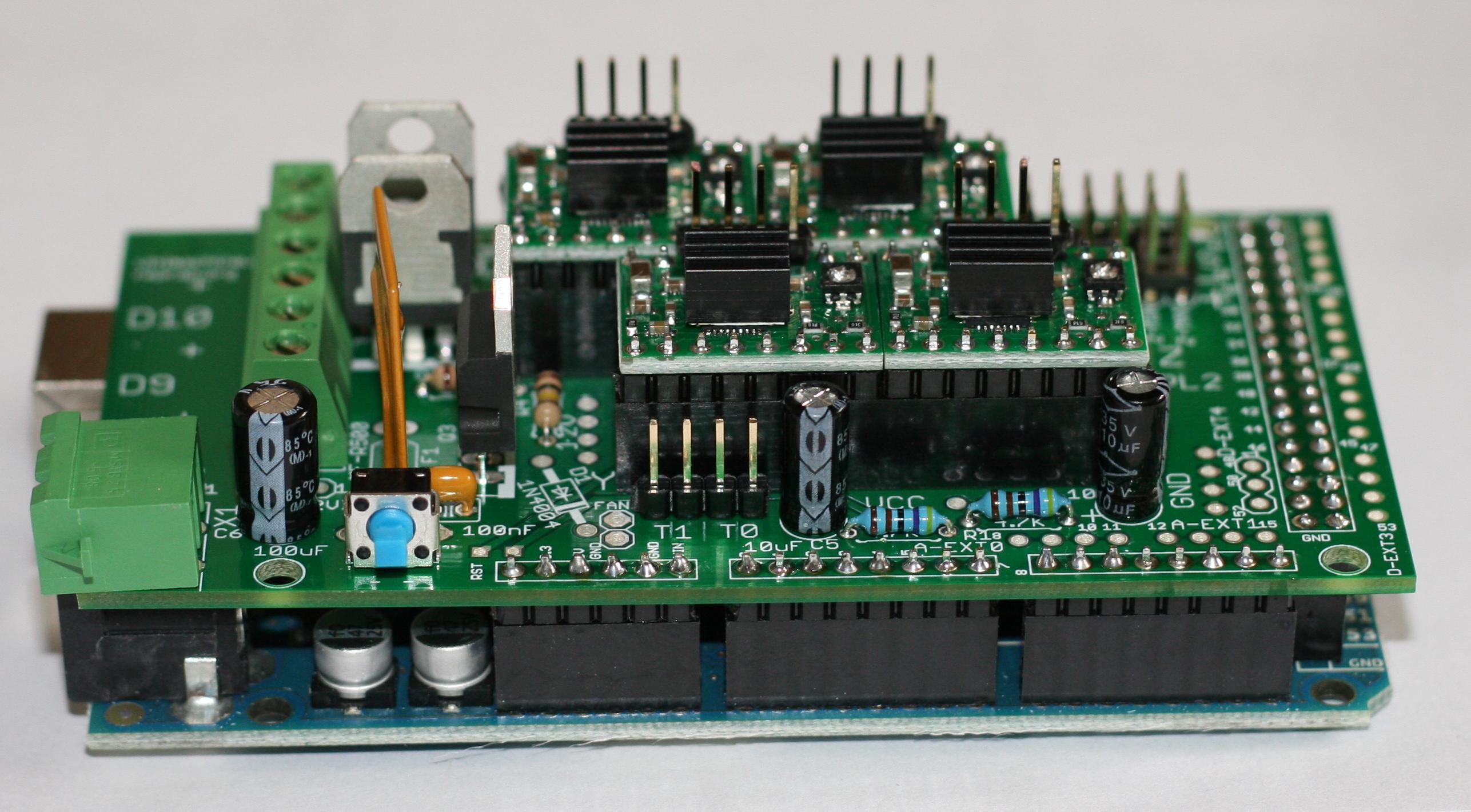

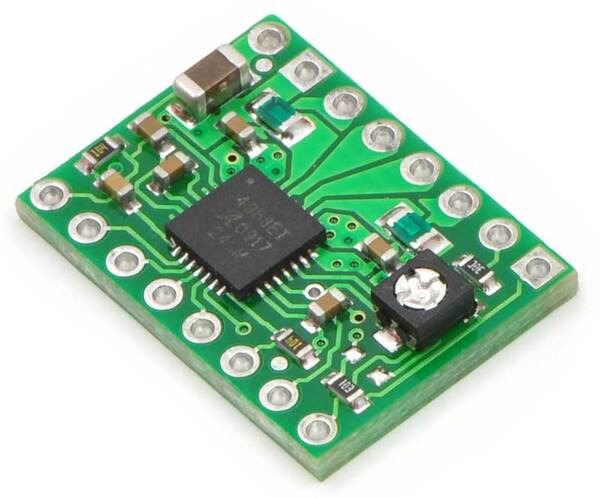

What happens when you are done putting everything together? This is one thing many people overlook when they start their build. Make sure you have the latest firmware for your electronics. Each type of electronics (be it RAMPS, Gen6, etc. ) will have slightly different firmware. For example, when I finished my build, a new type of firmware for Gen6 had been released, the Marlin firmware. Newer versions of firmware generally have more features than the old, such as stepper acceleration. Please, make sure you have the Arduino software downloaded. You will need to calibrate your electronics, this is done by modifying the code directly.

You will need a way to convert your models to g-code; this what the electronics will receive from the computer. When I first finished my printer Skeinforge was all the rage. Now there seem to be a few other options for generating g-code, which I have not had time to look into. Do your research in your downtime during the build. There is nothing worse than getting finished with your printer, then realizing you need to spend another week just to understand the software. I know you will want to do your first print the second you have everything hooked up.

The last bit of software you will definitely want is not really a program. A while ago, Prusa released a nice calculator which you can use to calculate your step sizes. This makes configuring your printer a breeze.

Conclusion

I'm sure that I am missing quite a lot of important things, but this should get you started. What this article should show you, is that it is important to think ahead when you are working on a RepRap. What did you find to be useful during your build? Let us know in the comments!

You will need a way to convert your models to g-code; this what the electronics will receive from the computer. When I first finished my printer Skeinforge was all the rage. Now there seem to be a few other options for generating g-code, which I have not had time to look into. Do your research in your downtime during the build. There is nothing worse than getting finished with your printer, then realizing you need to spend another week just to understand the software. I know you will want to do your first print the second you have everything hooked up.

The last bit of software you will definitely want is not really a program. A while ago, Prusa released a nice calculator which you can use to calculate your step sizes. This makes configuring your printer a breeze.

Conclusion

I'm sure that I am missing quite a lot of important things, but this should get you started. What this article should show you, is that it is important to think ahead when you are working on a RepRap. What did you find to be useful during your build? Let us know in the comments!